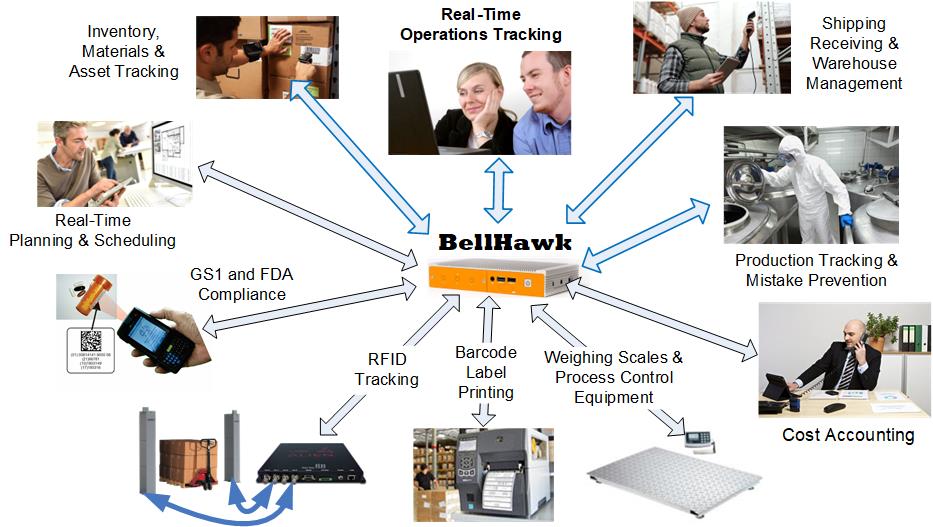

BellHawk is an integrated real-time inventory tracking system that has many capabilities.

BellHawk is affordable for even smaller industrial organizations with licenses to use the BellHawk software ranging in cost from around $500/month to around $1,500/month depending on whether this is for a simple barcode work-in-process tracking system or as a fully integrated manufacturing execution and warehouse management system

Manufacturers and industrial distributors have been typically able to save between $50,000 and $150,000 dollars a year by replacing the use of paper forms and manual keyboard data entry for capturing operational data with the use of BellHawk.

BellHawk typically runs on an inexpensive ruggedized Industrial Internet of Things (IIOT) computer at each site but can also be run on a Windows Server computer at a remote data center, in the Cloud.

BellHawk can be used stand alone or can automatically exchange data with a wide-range of ERP, accounting, or CAD systems, as well as with customer and supplier supply-chain systems.

BellHawk tracks the receipt of raw materials, their conversion into intermediate materials and finished products and then tracks the picking, packing and shipping of those finished products to customers.

BellHawk enables manufacturers to rapidly and cost effectively implement barcode tracking systems to track their inventory and their manufacturing operations in real-time. This includes tracking the status of work-in-process for customer orders in real-time as well as tracking the labor, materials, and machine time required for each job.

BellHawk also enables industrial distributors to track their warehouse operations in real-time, including secondary operations such as kitting, assembly, repackaging, and relabeling.

For more information about the BellHawk software, please click on the following links:

| Cost Savings | Technology |

|

Overview | Capabilities |

| Applications | Videos | Software Products | User Manuals | Data Sheets |

| Background | Partner Info | Frequently Asked Questions | Availability | White Papers |

| Technology |

|

Capabilities |

| Availability | Overview | White Papers |

| Background | Data Sheets | Videos |

| Cost Savings | Software Products | User Manuals |

| Partner Info | Frequently Asked Questions | Applications |

Copyright © 2025 Milramco LLC