One of the biggest impediments to effective management of industrial operations is not having easy real-time visibility into the current status of inventory, jobs, work-in-process, customer orders, and shipments.

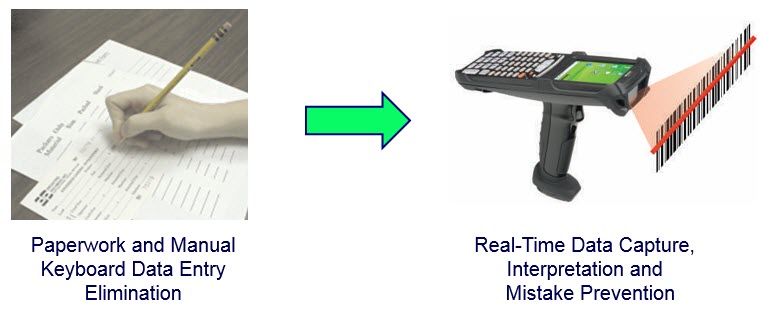

Many industrial organizations still rely on the use of paper forms and subsequent manual keyboard data entry into spreadsheets or other software applications. As a result, information about operational status and problems that occur is not available to managers until it is too late to take corrective action.

Also the use of paper forms combined with manual keyboard data is time consuming and mistake prone, resulting in higher than necessary overhead costs to enter the data and then to correct the mistakes that have been made.

With BellHawk Online data is captured in real-time. Typically this is done using barcode scanning and mobile computing technology but sometimes, where appropriate, RFID scanning is also used.

The big benefit of performing electronic data capture is that the data can be immediately checked for mistakes, which are easily corrected at time of data entry, and then the resultant information can be made available immediately, in real-time, to everyone who needs it.

The real-time error checking is not only used to prevent data entry mistakes but is also used to provide point-of-action warnings when an operational mistake is about to be made, such as picking the wrong materials for a job or customer order.

BellHawk Online uses electronic data capture to track the receipt and put-away of raw materials, their transformation into finished products, including tracking work-in-process, and the picking, packing, labeling, and shipping of finished products to customers.

The captured data is also processed in real-time to capture operational cost information, materials traceability history data for regulatory compliance, and other operational performance data.

Please click here to learn more about the Operational Tracking and Traceability Capabilities of BellHawk.

| Cost Savings | Technology |

|

Overview | Capabilities |

| Applications | Videos | Software Products | User Manuals | Data Sheets |

| Background | Partner Info | Frequently Asked Questions | Availability | White Papers |

| Technology |

|

Capabilities |

| Availability | Overview | White Papers |

| Background | Data Sheets | Videos |

| Cost Savings | Software Products | User Manuals |

| Partner Info | Frequently Asked Questions | Applications |

Copyright © 2025 Milramco LLC