How BellHawk Tracks Work-in-Process Materials

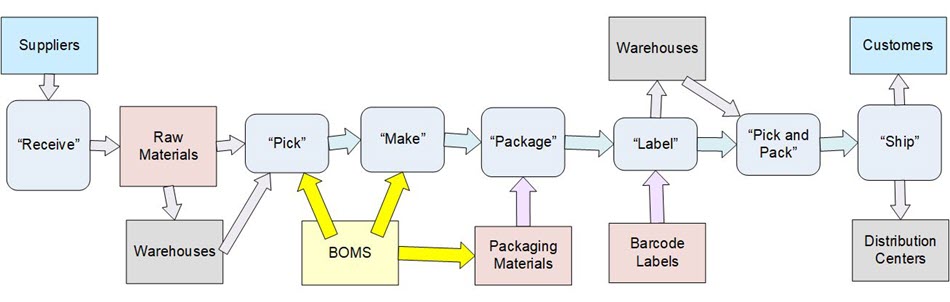

The BellHawk real-time data collection software tracks the receipt of raw materials, their transformation into intermediate and finished materials, as well as the picking,

packing, and shipping of the finished products.

BellHawk provides three alternative base systems for work-in-process data collection and materials tracking:

- SPTS -Simple Production Tracking System, which tracks batches of material through a sequence of operations on a work order, including capturing the labor time

required and the piecework quantities made.

- MTS - Material Tracking System, which performs the tracking of the raw, intermediate, and finished materials using license-plate-number container tracking methods.

This includes tracking each part or container of parts

as they move from work center to work center.

- RTOPS - Real-Time Operations Tracking System, which combines the features of SPTS and MTS and tracks the transformation of materials based on work-order

operations, which typically relate to the processing of a batch of materials, but which can also relate to the assembly, test, and repair of serial numbered equipment.

RTOPS can also track the transformation of materials by in an industrial warehouse.

MTS and RTOPS can be used with the BellHawk WMS Warehouse Management System option to track warehouse operations, such as receiving, picking, packing, and shipping,

as well as kitting, repacking, relabeling, and palletizing operations.

Comparison of Methods

- If all that is required is to see the real-time status of each customer order and the customer order consists of a single batch of materials or a single item then

simply use BellHawk SPTS to record when each work-order operation starts and ends. This is the simplest approach to getting real-time visibility into the status of each customer

order

- If the primary goal is to see the status of all the different materials related to work order or a customer project then BellHawk RTOPS should be used to track the receipt of

raw materials, and their transformation into work-in-process, intermediate and finished materials.

- If the primary goal is to track the picking, packing and shipping of finished products, then the BellHawk MTS should be used in conjunction

with the BellHawk WMS option. Such applications may also require the BellHawk TAG barcode label printing option.

- If the primary goal is to capture a materials traceability history so that this can be used to track back from defective finished

products to the raw materials used and to track forward from defective ingredients to the products in which these ingredients were used,

then RTOPS is essential.

- If the primary goal is to accurately capture labor and materials cost data then RTOPS should be used. This can be augmented by

capturing the setup, run, and down times of the equipment or machines used, if needed.

It is recommended that clients start with the simplest method that meets their initial objectives. Then clients can always upgrade their BellHawk software to include the additional capabilities they may need in future.

Please click here to learn more about The Work-in-Process Tracking Capabilities of BellHawk.